What can be made from sheep wool, types and classification of fibers

Wool is widely used in many areas of life. This material has firmly taken its rightful place among the most useful materials that surround a person. It is difficult to list all that is made from sheep's wool today. Products made from this fiber reliably protect us from the cold. Soft and fluffy pieces of clothing in a variety of colors will cheer you up. The beneficial properties are used in the treatment of diseases.

History

Scientists believe that woolen fiber appeared before linen. Our ancestors learned to process sheep skins before mastering textile technology. Archaeological research suggests that the Egyptians tamed the animal several thousand years ago. A sample of wool fabric found on the banks of the Oka River proves the appearance of a loom in ancient times.

In ancient Rome, in time immemorial, they learned how to breed sheep. The result is a merino breed called tarantino. The fiber was used to make clothing.

Material characteristic

Woolen products are distinguished by useful properties. This is due to the fact that the fiber is mainly composed of the protein keratin. Users note the following positive properties of the material:

- The ability to absorb human sweat while maintaining natural body temperature. Sweat evaporates into the atmosphere.

- Self-cleaning property. Natural fiber does not accumulate germs and harmful bacteria.

- Healing properties. The remedy lanolin is made from the sheepskin. It heals wounds, removes diaper rash and relieves inflammation. Wool normalizes blood pressure and sleep, soothes muscles and joints.

The fluffy thin fleece is of the greatest value. It is this product that underlies the production of environmentally friendly branded clothing models.

Production, processing, sorting

The fiber production process has several stages:

- She used to shear sheep. In recent years, electrical appliances with removable attachments have replaced mechanical shears. They greatly facilitated the work of the foreman and ensured high productivity. The fleece is removed carefully so as not to harm the animal and not damage the fiber. Dirty sheepskin should be removed immediately.

- Sheared fiber is graded according to length, color, thickness and waviness. The best is the fleece of the spring haircut.

- Washing should not be accompanied by fiber damage. Therefore, this work is trusted by knowledgeable people.

- After washing, the material is passed through a combing machine.To fix the lanolin, the fiber is treated with oil.

- The wool is combed with brushes. Then, in equal strips, they are passed into the machine to obtain a thin thread, which is called roving. It is sent to a spinning machine where several threads form one.

On another machine, a finished fabric is obtained for the manufacture of various goods.

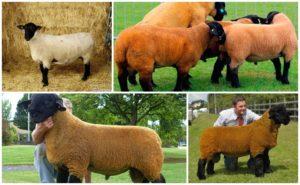

Directions in woolen animal husbandry

Sheep wool can have such qualities as shine, color and others. They depend on many conditions and parameters:

- sheep breed and age;

- haircut period;

- feeding and grazing conditions.

There are 4 known directions in woolen sheep breeding. Basically, rocks differ in fiber thickness.

Fine-wooled

Fibers of fine-wooled animals have their own classification. They are divided into two types:

- The thinnest are in the range of 10-14 microns.

- Thin - from 15 to 25 microns.

The fiber length should be 75-100 mm. Such material is obtained from wild sheep, merino. The undercoat of some coarse-haired breeds also has the properties of a fine-wool fiber. Merino sheep are bred in Australia, New Zealand, South Africa. The conditions of deserts and steppes are suitable for them. The quality standard is the fiber of Australian and New Zealand merino with a thickness of no more than 16.9 microns. The elasticity of the material allows it to withstand up to 20,000 folds.

Semi-fine wool

Such raw materials are obtained from sheep raised in mild humid climates. These include:

- tsigai breed;

- new Russian breeds;

- Romney Marsh breed, Lincoln from England.

This includes a cross between some fine wool and coarse wool breeds. Fiber thickness - from 26 to 40 microns.

Semi-coarse

The fiber thickness of semi-coarse-wool rocks ranges from 41 to 60 microns. Raw materials with such parameters will be obtained from sheep raised in mountain conditions. These are coarse-haired and some varieties of long-haired breeds. The fiber of these sheep is coarser than merino, but it is distinguished by its strength and sufficient length (20-25 microns). It is convenient to spin it. Products made from such raw materials are distinguished by a silky sheen.

Coarse-haired

The habitat of coarse-wooled sheep is deserts and semi-deserts. Coarse fiber is also obtained from meat, meat and dairy animals. The fiber thickness reaches 61 microns. Raw materials are used for the manufacture of outerwear, felt and carpets, which are durable.

Application of wool

Sheep wool is widely used in various fields. It is used in the manufacture of many products, namely:

- Carpets. Manufacturers use wool for the base, and make the surface fleecy. Such carpets are distinguished by their high density and beauty.

- Bed dress. Six is used in the manufacture of quilts, pillows, rugs that are hygroscopic.

- Clothing. Woolen fiber is used to sew and knit socks, stockings, sweaters and other garments. Woolen garments keep you warm.

- Towels. The material absorbs moisture well and provides comfort after bath procedures.

For all its advantages, woolen fabric has minor disadvantages. Some types of fiber have a biting habit.

How is sheep wool made into clothing?

They learned to make clothes from this material hundreds of thousands of years ago. If earlier these were simple capes made of poorly processed hides, now the most modern clothes are prepared from woolen fiber.

The loom has revolutionized the production of wool products. New technologies make it possible to create the finest threads for the manufacture of exquisite goods.Manufacturing processes are mostly automated and allow the production of products in huge quantities.

The subtleties of processing at home

The wool processing process has undergone major changes over the past decades. In the 90s, Russian sheep breeding fell into decay. The harmonious fiber procurement system has disintegrated. The number of livestock fell sharply. Gradually, raw material cultivation technologies have become a thing of the past.

Over time, the situation began to change for the better. Farming and peasant farms appeared. The need to process their own products made the villagers remember the craft of the recent past.

Livestock breeders realized that selling wool immediately after shearing was unprofitable. Moreover, sheep breeding has acquired the character of a family business. In the conditions of developed technologies, there is no need to talk about a full cycle of processing raw materials on site. Primary processing is justified and includes the following steps:

- Sorting. The process is tedious and responsible. Fibers from even one animal differ in quality, length, purity.

- Cleaning. Raw materials have to be cleaned of plant debris, pieces of manure and other unnecessary elements.

- Flushing. A mandatory procedure that brings the material into a presentable form. Special means are used for washing. For each kg of raw materials add 250-300 gr. powder. The washed wool is rinsed in hot water. The number of procedures depends on the degree of fiber contamination.

- Drying. The raw materials are laid out on a grid in a thin layer. The thickness should not exceed 1.5 cm. Otherwise, the wool will dry for a long time.

- Combing. This work is done in two ways. The most popular is the carded method, based on brushing with fine-bristled brushes from thin but resilient metal wires. The second method is called combed, but it is almost never used.

You can make yarn from the finished fiber with your own hands. Almost no one uses old spinning machines anymore. To obtain high-quality yarn, electric machines are used.

How to make a sheep wool blanket with your own hands?

Blankets are made from wool with their own hands. The process is simple, but time consuming. It consists of several stages:

- Purchase of material. On the market you can find both clean and unwashed wool. The washed material is more expensive, and it will take 2 times more. A blanket for an adult will need 2.5 kg.

- Interrupting the fiber. For this work, you need to prepare a long stick. The wool should be spread out, lightly sprinkled with water and beaten on it, turning it over regularly. The amount of material should visually increase 2 times.

- Preparing the cover. It is made from calico or calico. One side is left open. The product is turned inside out.

- Wool styling. The material is laid out on spread gauze. The fiber should be flattened by hand and rolled at both ends. After that, you need to grab the unsewn edge of the cover and pull it onto a roll. Then turn the cover in the opposite direction. The wool will be inside. After gently smoothing, the blanket is completely sewn up.

- Quilting a blanket. For this work, you will need thick cotton thread and a large needle. You need to step back from the corners by 10 cm. The blanket must be pressed to the ground so that it lies motionless. The stitches are done at a distance of 10 cm. As the thread is completed, it is increased.