Manure removal systems in the barn, top 4 methods and manure processing

Correct organization of manure removal in barns is necessary to maintain sanitary standards. At the same time, the high-quality work of the personnel ensures the functionality of the entire agricultural complex. The health of livestock should be of great importance. Therefore, cowsheds are equipped with devices for cleaning, collecting, and removing animal waste. The construction of manure storage facilities near the barns makes this easier.

The meaning of manure removal

Cattle are kept completely clean. The bases are cleaned regularly. Warehouses are also subject to regular cleaning. Sewage accumulates rapidly, so you cannot start cleaning.

Unsanitary conditions increase the risk of infectious diseases in both livestock and humans. Cleaning the premises improves the microclimate. Cleaning helps to reduce the level of ammonia and nitrogen in the air. To avoid such problems, farmers equip their barns with a manure removal system.

Waste products are used as fertilizers. Manure contains nitrogen, phosphorus, potassium, which enrich the land. This brings additional profit for the agricultural complex. The following waste forms exist:

- Liquid.

- Liquid fraction after separation.

- Solid fraction after separation.

- Litter.

- Influent.

Cleansing includes the following operations:

- Removal.

- Transportation.

- Recycling.

- Storage.

- Using.

Manual cleaning of premises is not efficient and leads to huge labor costs. Automatic devices perform the work efficiently and quickly. Which cleaning system is best for the complex depends on the size of the barn.

Cleaning methods

On farms, mechanical and hydraulic manure removal devices are used. Suitable equipment is selected according to the way the animals are kept. The choice also depends on the area of the room.

Self-alloy systems

The self-alloyed cleaning method is referred to as hydraulic equipment. For this, pipe-channels are used, which have a slippery coating. The manure slides down at a natural slope that forms in the pipe. The channel-pipe is filled with water, and the slurry flows through it to the manure tank. Devices are of continuous and periodic action.

Equipment for water jetting

The system consists of a water tank, a water channel, a closed grate, a damper that restricts the access of feces outside the channel. A waste collection container is provided on the opposite side. Manure seeps through cracks. The strong pressure of water washes it away. The water wash uses a huge amount of water, which increases the humidity in the barn.

Conveyor based machines

The conveyor is chain and screw. The chain works in tied barns, removes manure from the litter and loads it onto transport. The horizontal part of the device is used for cleaning the manure channel, and the inclined part is used for loading waste into the machine. The system serves over 100 stalls. The screw conveyor transports the manure to the manure storage. The device is longitudinal and transverse.

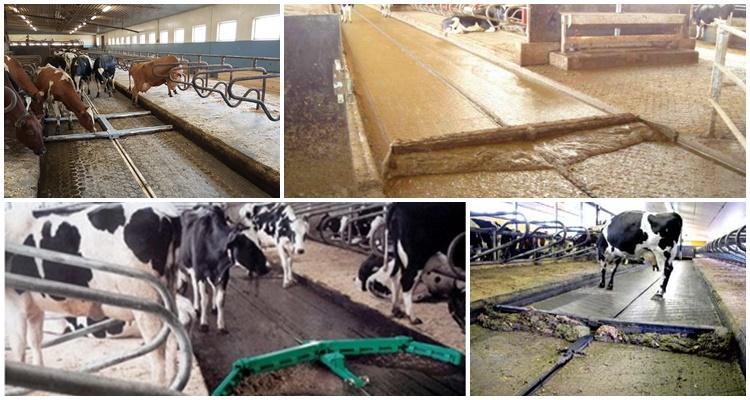

Delta scraper equipment

The system collects the manure using open scrapers. The equipment works in open passages and is safe for animals. The scraper consists of four parts. The reciprocating motion of the scraper scrapes manure throughout the entire area, including the entire room and hard-to-reach corners.

Manure processing

Large agricultural complexes containing a large number of cattle provide a constant collection of animal waste. After that, the manure must be processed for further use. For this, liquid and solid particles are separated. The liquid fraction is used as fertilizer for watering the plant, thanks to the nitrogen, potassium and phosphorus included in the composition. This avoids the use of chemical fertilizers.

In barns, systems are used that mix manure, grind solid fractions using a submersible pump, and squeeze out the liquid fraction with a separator.

Nutrients and beneficial trace elements are additionally added to the resulting mixture. The manure storage tank stores raw materials until the moment of use. Solid waste is used for composting. Litter for animals in the barn is made from the solid fraction by processing.

With proper cleaning of the premises, the environment is not polluted, the productivity of cattle remains in normal mode. Nothing threatens animal health.