Why the separator can be bad at separating cream from milk and how to set it up

No one will argue that homemade sour cream, cream and butter are several times tastier and healthier than store-bought ones. It is enough to purchase a simple device - a separator, and there will always be fresh dairy products on the table. But after a while, many have difficulties with the unit, and the question arises why a brand new separator does not separate the cream from milk poorly. To prevent and fix this problem, it is enough to know how to assemble and operate the device.

Separator assembly rules

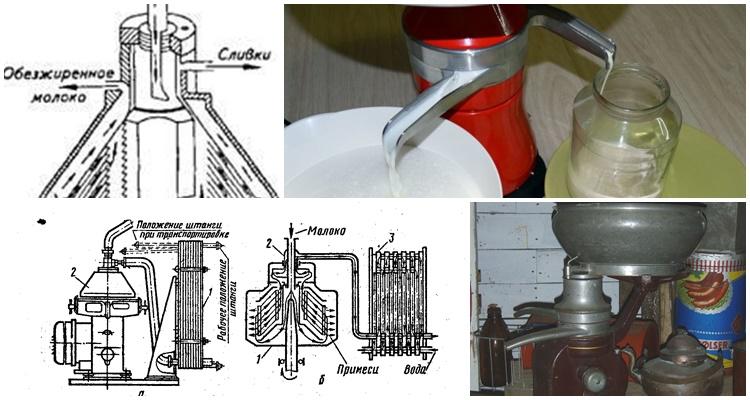

A separator is a mechanical device that drives cream from fresh milk and makes butter. They are manual and electric, but inside, both are arranged the same:

- Enclosure (includes power button and cord if unit is powered).

- Engine.

- Drum.

- Receivers for skim milk and cream.

- Float chamber and float.

- Milk receiver.

- Traffic jams.

When all the details have been studied, you can safely assemble the separator and get ready for work. Phased assembly will not take more than 10 minutes:

- First, the drum must be secured to the top of the motor shaft. It should sit lightly, but hold tight. It is better to do a few manual turns for reliability and absence of distortions.

- Further, the receivers are put on the top of the structure. The first is the skimmer, followed by the cream. It is important not to be confused, since one of them has a notch that must be aligned with the hole in the case. The cream receiver can be installed in any direction as desired.

- A float chamber is attached to the sinks, and the float itself is installed on top in the form of a white or transparent disk.

- The penultimate stage is the installation of the bowl. It does not need to be fixed. The bowl itself will hold firmly under the weight of the milk.

- At the end, all that remains is to install the plug / tap It regulates the flow of milk into the bowl.

How to adjust the device

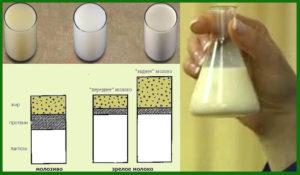

One of the first difficulties that separator users face is the lack of fat in the cream. The separation takes place in the drum of the device, where, under the action of centrifugal force, the milk is decomposed into whey and cream.

This is easy enough to do. It is necessary to tighten the screw in the upper drum cymbal. The maximum fat content of cream is from 0.05. To achieve it, screw the screw all the way, and then make one and a half turns back.

In this standing, the separator will work for a maximum of 15 minutes.Then it needs to be disassembled and rinsed, since the grease clogs the parts. It is optimal to set the screw value by 3-3.5 turns. It should be borne in mind that the fatter the cream, the lower their ratio to the milk used.

Older separator models were devoid of customization and made products of one fat content. In them it was impossible to regulate the density of the liquid. New devices, for example, the “IRID” separator, are suitable for the production of both liquid cream and thick cream.

Reasons why the separator does not work

The device may not work at all or may not work properly due to breakage or assembly errors.

How are the defects of the mechanism and the features of the separator's operation related:

- The drum does not respond when a button is pressed. Everything is simple here: either the button is faulty, or the internal contacts have come off, or the engine itself is out of order.

- The separator dispenses cream of the wrong fat content and thickness even with the correct screw settings. This means that the adjusting hole is clogged. Cleaning with a brush will quickly improve the situation.

- Separator parts rattle when starting. If there is no milk in the bowl, then extraneous sounds are the norm. If there is liquid, but the grinding remains, the reason is improper assembly of the device components.

- During operation, impacts are heard inside the separator. There are several reasons for this. The drum may have jammed or parts of the drum may not be assembled correctly The nuts that secure the motor are loose. The motor shaft is bent or deformed. The separator is tilted. Factory defects are to blame, and it is worth carrying the device for repair under warranty.

- The drum is not picking up the required pressure and number of revolutions. Option one: insufficient power supply. Option two: faulty socket or wiring. Option three: the engine of the unit is broken.

Why the separator does not separate the cream

It happens that the separator ceases to fulfill its direct purpose even with an increase in the drum speed. Why is this happening?

- Milk does not enter the drum. The clogged hole in the plug or faucet is to blame for this.

- The sealing gum between the parts of the drum is loose or has been broken. Ideally, the elastic should be whole, round.

- The thicker the cream, the faster the internal parts of the mechanism clog. If you do not rinse them in time, the work will stop.

- If the device worked continuously for more than half an hour, and then stopped driving the cream, then, probably, it clogged or broke from overload.